About BECS MASTER

BECS MASTER is a brand name registered by Chiyoda Kogyo. We are one and only domestic manufacturer of fabricating machinery that covers all metal processing completely in-house.

Processing range as follows (mainly bending):

- Processing conditions

Cold forming (No heat applied onto materials)

- Quality of materials

Steel, copper, aluminum, stainless steel, brass, titanium, magnesium alloy, duplex cladding tubes

- Shape of materials

Tube/pipe(round, square, profile, aluminum extrusion, copper wire, flat bar, rolled steel/dd)

- Size of materials

Wire φ1 MIN~round tube φ300 MAX

Reading today’s trend, BECS MASTER now has product line-ups for not only metal but also rubber, resin and plastics materials.

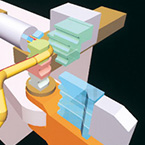

For BENDING, a method of rotary draw bending is the most commonly used. Other methods such as bending of compression, roll, stretch, press and extrusion (multi-forming) are also available.

- Models:

- CNC bender, rotary bender, serpentine bender, two-starts bender, stretch bender, multi-former bender, extrusion bender, hydraulic bender

“EXPAND/SWAGING” is to perform expanding, beading, flaring, burring, swaging or combined processing onto the end part or the middle part of tubes.

- Models:

- Punch press, roll former, eccentric plug former, hydrostatic bulge former, jaw collet former, tube rolling former

“CUT” means process of cutting standard size (5.5 m) tube materials made at tube mills to predetermined length according to designated uses.

1 to 10 pieces of non-steel coiled tubes can be processed to fixed length at a time while straightened.

Puncturing process on the middle part of tubes is also included in the cutting process.

- Models:

- Roll cutter, metal saw cutter, press cutter, blade cutter, Laser cutter

“SIMULATION/MEASURING” are procedures required for quality checks such as examinations of processing accuracy, inspections, data measuring and designing of tubes, which is crucial to design sectors.

A 3D tube measuring instrument is used for check of bent tube shapes and inspection of accuracy, while simulation software (Bendershot) is an indispensable item in bending data creation, interference check, quality control and designing of tubes.

- Models:

- CCD camera type 3D tube measuring machine, Bendershot(simulation software package)

BECS MASTER selects a machine according to specifications of designated tubes, manufactures complex machines with two or more functions, or can build up a system line combining these machines as a labor-saving automation line.

As a manufacturer of tube deforming processing machinery, BECS MASTER has satisfied customers with in-house integrated tube fabricating system production on the basis of fundamental fabricating technologies which we have developed 70 years.

Moreover, with our comprehensive technical service after delivery, we have earned the strong trust of customers. The brand of BECS MASTER is the symbol of our pride.